应力应变法求解弹性系数

现在我要用分子动力学求解有限温度下弹性系数,由于势函数是机器学习势。所以首先,我们应该验证势函数的可靠性。

也就是说,首先验证,在0K下,对象是小胞时,通过DFT与MLIP-MD计算得到的Cij的差距。然后在高温下跑大胞的MD,计算有限温度下的Cij

原理及编程

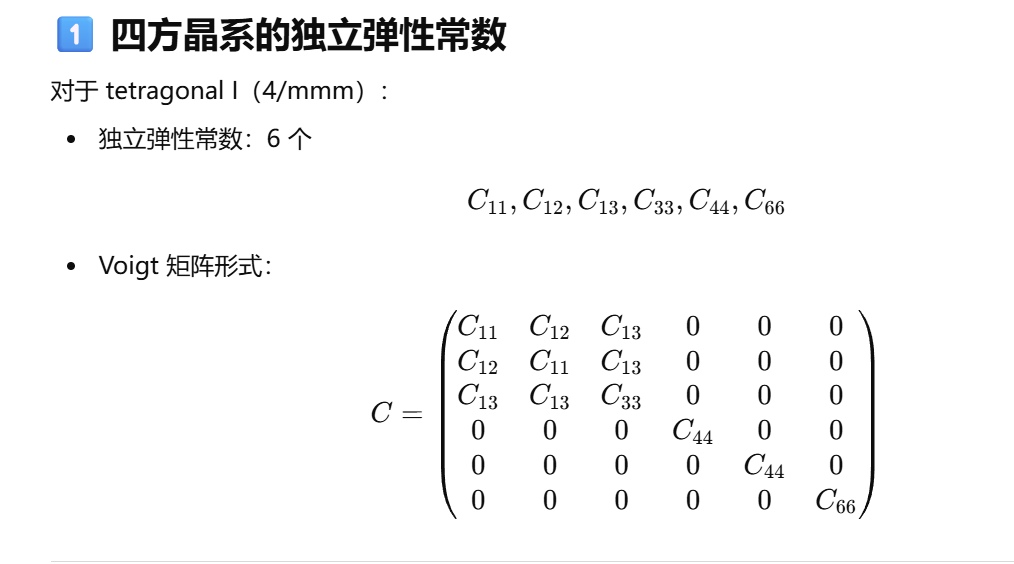

这里以四方晶系-1为例,也就是有六个独立的弹性系数。目前,我所见过的所有,应力应变法求解弹性系数的计算思路都是拟合。

我们先看一下所要求解的弹性系数矩阵的样子。

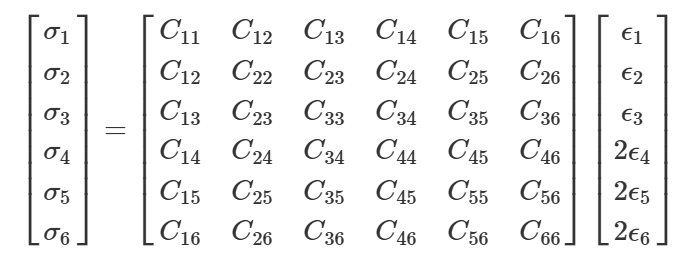

根据线弹性假设,

$$\sigma = C * \varepsilon$$,给出应变,通过线性组合,可以表示出应力,即公式

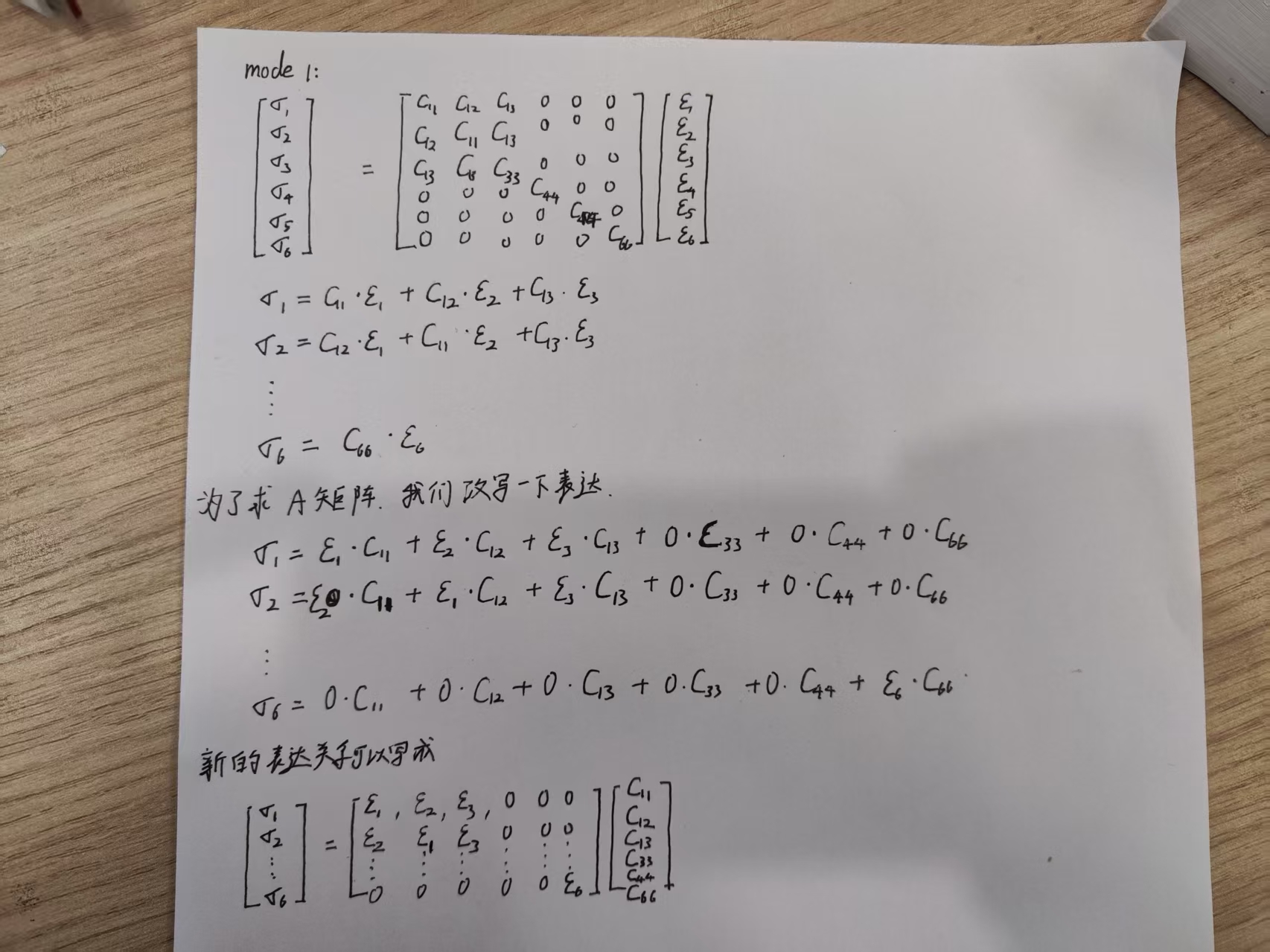

但是,要想使用numpy.linalg.lstsq进行拟合,还需要重新表达一下这关系。

因为lstsq的工作原理是B = A * X,根据已知应变A、应力B,用最小二乘法拟合一个为列向量的系数,X,(这里即Cij)

现在,我们专注于A矩阵的写法。

可以看到,应变A矩阵是由所施加的应变,也即是变形模式,以及弹性系数矩阵的形状共同决定的。(Cij矩阵决定了A矩阵的形状,而变形模式决定了它具体的元素值)

有几点需要澄清,待求解的Cij可能不止6个。比如说,7个的时候,需要X列向量是7行,A矩阵是七列吗?显然,不需要也不能。因为一种应变模式只能提供六个线性方程组,6个应力最多只能包含6个弹性系数的有效信息。这也是为什么,低对称晶系需要更多变形模式的原因。因此,我们在选择变形模式的时候,要合理。对于大于6个弹性系数的体系,要让弹性系数间尽量解耦——保证一个变形模式内,涉及的弹性系数最多为6个。通过选取多个变形模式,比如说两种,这样有2个A矩阵,12个方程,把两个A矩阵堆叠起来,就能求解7个Cij了

这里我放上一个具体的脚本,提供一些思路

import numpy as np

from ase.io import read,write

#针对四方相计算弹性常数C11,C12,C13,C33,C44,C66

prim = read('ysz_42.xyz')

ups = [-0.03,-0.01,0.01,0.03]

modes = [0,1]

Ms = []

for mode in modes:

for up in ups:

if mode == 0:

strain_voigt = np.array([up,0.,0.,0.,0.,0.])

strain_matrix = strain_matrix_1 = np.array([[up, 0., 0.],

[0., 0., 0.],

[0., 0., 0.]])

deform_matrix = np.eye(3)+strain_matrix

atoms = prim.copy()

cell_new = deform_matrix @ atoms.cell[:]

atoms.set_cell(cell_new, scale_atoms=True)

write('deformcell_{}_{}.xyz'.format(mode,up),atoms)

#有了应变模式和应变幅度,即可确定M矩阵

M_matrix = np.array([[up,0.,0.,0.,0.,0.],

[0.,up,0.,0.,0.,0.],

[0.,0.,up,0.,0.,0.],

[0.,0.,0.,0.,0.,0.],

[0.,0.,0.,0.,0.,0.],

[0.,0.,0.,0.,0.,0.]])

Ms.append(M_matrix)

if mode == 1:

strain_voigt = np.array([0.,0.,up,up,0.,up])

strain_matrix = np.array([[0., up/2, 0.],

[up/2, 0., up/2],

[0., up/2, up]])

deform_matrix = np.eye(3)+strain_matrix

atoms = prim.copy()

cell_new = deform_matrix @ atoms.cell[:]

atoms.set_cell(cell_new, scale_atoms=True)

write('deformcell_{}_{}.xyz'.format(mode,up),atoms)

M_matrix = np.array([[0.,0.,up,0.,0.,0.],

[0.,0.,up,0.,0.,0.],

[0.,0.,0.,up,0.,0.],

[0.,0.,0.,0.,up,0.],

[0.,0.,0.,0.,0.,0.],

[0.,0.,0.,0.,0.,up]])

Ms.append(M_matrix)

Ms = np.array(Ms)

Ms_2d = Ms.reshape(-1, 6) # 自动把 8*6=48 行展开

print(Ms_2d.shape) # (48, 6)

print(Ms_2d)

#C_fit, residuals, rank, s = np.linalg.lstsq(Ms_2d, sigma_vec, rcond=None)

代码中的M,就是上述的A矩阵。除此之外,代码是先把变形模式1的不同幅值的A矩阵堆叠起来,然后再把变形模式2的不同幅值的A矩阵堆叠起来。

顺序是没有影响的。本质上就是拟合2 * 4 * 6 = 48个应力应变关系涉及的6个Cij。就是把矩阵行交换,是不影响有效信息的。

最后,有了堆叠后的应变A矩阵和应力向量,简单的使用lstsq拟合即可。

此外,也可以观察到,这些A矩阵中的每一行中,只有一个不为零的值,其实是因为我们的四方晶系比较简单,合适的应变模式选取让Cij之间完全解耦。

这种情况下,如果不嫌弃麻烦,也可以从这个48个方程中挑选出对应的,某个Cij与有些应力的关系,单独拟合。

0K下的弹性系数

0K下DFT计算略过,使用MLIP也不需要跑MD,只需要对变形进行评估得出应力即可。

手动法:

calorine

我们用的小胞不再改变体积。我们需要做的就是施加应变,然后计算应力。

这个过程其实是:(1)弛豫(2)输出应力

我们这里用与nep配套的calorine软件包结合ase进行弛豫。

#对结构进行弛豫并计算应力

import numpy as np

from ase.io import read,write

from ase.units import GPa

from calorine.calculators import CPUNEP

from calorine.tools import relax_structure,get_elastic_stiffness_tensor

prim = read('CONTCARYSZ')

calc = CPUNEP('nep.txt')

#ups = [-0.006,-0.004,-0.002,0.002,0.004,0.006]

ups = [-0.006,-0.002,0.002,0.006]

modes = [0,1]

stresses = []

for mode in modes:

for up in ups:

if mode == 0:

strain_matrix = strain_matrix_1 = np.array([[up, 0., 0.],

[0., 0., 0.],

[0., 0., 0.]])

deform_matrix = np.eye(3)+strain_matrix

#每次拷贝一下原始结构

atoms = prim.copy()

#左乘变形矩阵

cell_new = deform_matrix @ atoms.cell[:]

#重新定义胞并缩放原子

atoms.set_cell(cell_new, scale_atoms=True)

#为变形后的晶胞绑定计算器

atoms.calc = calc

#弛豫结构

relax_structure(atoms,fmax=0.02,steps=300,minimizer='fire',constant_cell=True,constant_volume=True)

#输出应力

stress = np.array(atoms.get_stress())/GPa

stresses.append(stress)

if mode == 1:

strain_matrix = np.array([[0., up/2, 0.],

[up/2, 0., up/2],

[0., up/2, up]])

deform_matrix = np.eye(3)+strain_matrix

atoms = prim.copy()

cell_new = deform_matrix @ atoms.cell[:]

atoms.set_cell(cell_new, scale_atoms=True)

atoms.calc = calc

relax_structure(atoms,fmax=0.02,steps=300,minimizer='fire',constant_cell=True,constant_volume=True)

stress = np.array(atoms.get_stress())/GPa

stresses.append(stress)

np.savetxt('stresses.txt',stresses)

# prim.calc = calc

# cij = get_elastic_stiffness_tensor(prim, fmax=0.01,epsilon=0.001)

# print(cij)

calorine自带的cij计算器采用的不是应力应变法,没有深究。

这里结构优化的时候,一定要固定体积和晶胞形状,不然等于没有应变。

import numpy as np

from ase.io import read,write

#针对四方相计算弹性常数C11,C12,C13,C33,C44,C66

seed = '1'

#ups = [-0.006,-0.004,-0.002,0.002,0.004,0.006]

ups = [-0.006,-0.002,0.002,0.006]

modes = [0,1]

Ms = []

for mode in modes:

for up in ups:

if mode == 0:

strain_voigt = np.array([up,0.,0.,0.,0.,0.])

strain_matrix = strain_matrix_1 = np.array([[up, 0., 0.],

[0., 0., 0.],

[0., 0., 0.]])

#有了应变模式和应变幅度,即可确定M矩阵

M_matrix = np.array([[up,0.,0.,0.,0.,0.],

[0.,up,0.,0.,0.,0.],

[0.,0.,up,0.,0.,0.],

[0.,0.,0.,0.,0.,0.],

[0.,0.,0.,0.,0.,0.],

[0.,0.,0.,0.,0.,0.]])

Ms.append(M_matrix)

if mode == 1:

strain_voigt = np.array([0.,0.,up,up,0.,up])

strain_matrix = np.array([[0., up/2, 0.],

[up/2, 0., up/2],

[0., up/2, up]])

M_matrix = np.array([[0.,0.,up,0.,0.,0.],

[0.,0.,up,0.,0.,0.],

[0.,0.,0.,up,0.,0.],

[0.,0.,0.,0.,up,0.],

[0.,0.,0.,0.,0.,0.],

[0.,0.,0.,0.,0.,up]])

Ms.append(M_matrix)

Ms = np.array(Ms)

Ms_2d = Ms.reshape(-1, 6) # 自动把 8*6=48 行展开

# print(Ms_2d.shape) # (48, 6)

# print(Ms_2d)

stress = np.loadtxt('stresses.txt')

# print(stress.shape)

stress = stress.reshape(-1,1)

# print(stress)

cij, residuals, rank, s = np.linalg.lstsq(Ms_2d, stress, rcond=None)

c11 = cij[0][0]

c12 = cij[1][0]

c13 = cij[2][0]

c33 = cij[3][0]

c44 = cij[4][0]

c66 = cij[5][0]

M = c11+c12+2*c33-4*c13

C2 = (c11+c12)*c33-2*c13*c13

B_v = (2*(c11+c12)+c33+4*c13)/9.

G_v = (M+3*c11-3*c12+12*c44+6*c66)/30.

B_r = C2/M

G_r = 15./(18*B_v/C2+6/(c11-c12)+6/c44+3/c66)

B_vrh = (B_v+B_r)/2.

G_vrh = (G_v+G_r)/2.

E = 9*B_vrh*G_vrh/(3*B_vrh+G_vrh)

v = (3*B_vrh-2*G_vrh)/(2*(3*B_vrh+G_vrh))

with open('elastic_{}'.format(seed),'w') as f:

f.write(str(ups)+'\n')

f.write(f'C11: {c11}\n')

f.write(f'C12: {c12}\n')

f.write(f'C13: {c13}\n')

f.write(f'C33: {c33}\n')

f.write(f'C44: {c44}\n')

f.write(f'C66: {c66}\n')

f.write(f'E: {E}\n')

f.write(f'residuals: {residuals}\n')

f.write(f'rank: {rank}\n')

f.write(f's: {s}\n')

这个代码只适用于四方相-1,别的需要改动M矩阵以及输出cij时的处理。

有限温度下的弹性系数

首先在npt下保温一段时间,确定平均晶格常数。然后施加变形,在nvt下进行保温求出应力的时间平均。

npt保温

potential ./nep.txt

minimize fire 1.0e-5 300

velocity 10

time_step 0.5

dump_thermo 5000

dump_exyz 2000 1 1

ensemble npt_scr 10 1500 100 0 0 0 300 300 300 1000

run 100000

dump_thermo 100

dump_exyz 200 1 1 1

ensemble npt_scr 1500 1500 100 0 0 0 300 300 300 1000

run 200000

nvt保温

potential ./nep.txt

minimize fire 1.0e-5 300

velocity 10

time_step 0.5

dump_thermo 5000

dump_exyz 2000 1 1

ensemble nvt_bdp 10 1500 100

run 100000

dump_thermo 100

dump_exyz 200 1 1 1

ensemble nvt_bdp 1500 1500 100

run 200000